From AI Anxiety to Partnership: Time Creation Through Design

- Eric Olsen

- Nov 18, 2025

- 6 min read

FPW Symposium 2025 Blog Series, Part 6

"Will AI replace me?" The continuous improvement professional's question during our CI collaboration session captured a fear that rippled through every sector group. Yet in the same breath, participants complained about having no time for improvement work. The irony was stark: we simultaneously feared replacement by technology while drowning in work that technology could help manage.

This paradox—fearing AI while desperately needing its capabilities—became clearer as the symposium progressed. The real insight? AI anxiety and time poverty aren't separate challenges. They're symptoms of the same organizational design flaw: systems optimized for efficiency rather than adaptation. Consider email, which enables us to be drowned in work. Automation of bad design multiplies the problem. Social media follows this same pattern.

The AI Paradox Across Sectors

We may be experiencing waves of AI hype cycles as different capability and application pairs roll out. Each sector revealed different facets of technology integration anxiety:

CI Professionals faced an identity crisis. "We've spent careers becoming process experts. Does AI make us obsolete?" Their fear went beyond job loss to professional purpose. If AI can analyze processes and suggest improvements, what's left for human practitioners?

Technology Professionals warned about implementation risks. "Dirty data—AI quickly implemented could be a liability," one IT leader cautioned. They saw colleagues rushing to implement AI without understanding data quality, governance, or ethical implications. The tools meant to enhance became threats to organizational stability.

Manufacturing viewed AI as a non-negotiable survival tool. "Our competitors use it or they die. We use it or we die." No philosophical debates here—just pragmatic recognition that AI-enhanced operations represent table stakes for global competition.

Healthcare sought augmentation while preserving the human touch. "AI should enhance clinical decision-making, not replace bedside manner." They needed technology to handle the administrative burden while preserving the human connections that define care quality.

The pattern was clear: sectors closest to direct value creation saw AI as a tool for competitive survival, while knowledge workers experienced existential questions about their continued relevance. As one recently laid-off knowledge worker shared, he was trying to future-proof his career by moving closer to the business—from IT to Product Owner roles. Perhaps continuous improvement practitioners need to move closer to the value creation as well.

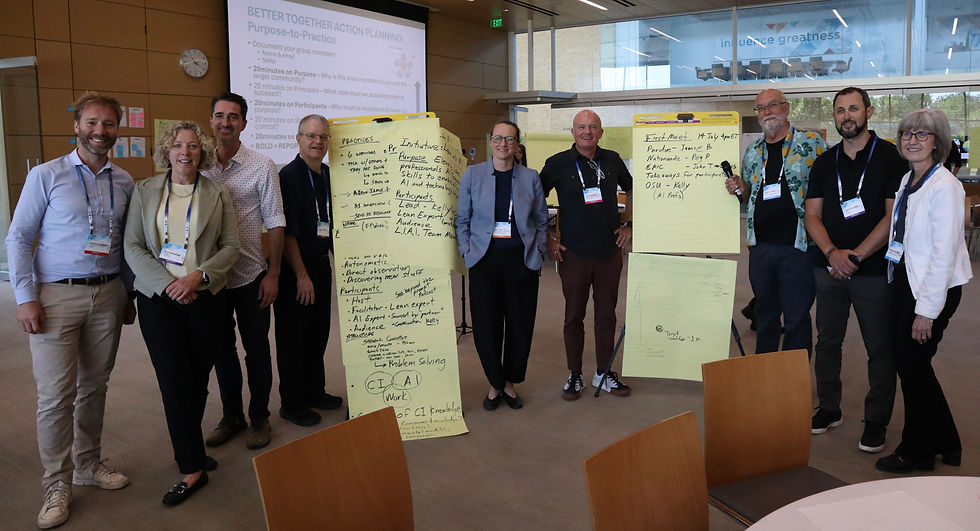

The Lean Into AI Response: 90 Minutes to Framework

The symposium's response to AI anxiety demonstrated our collective capacity for rapid, structured action. During Open Space Technology sessions on Friday, June 27, Kelly Reo and Eric Olsen convened interested participants. Within 90 minutes, they'd developed a three-tier learning framework:

Tier 1: Foundational AI Literacy

Demystifying terminology

Understanding capabilities and limitations

Identifying improvement applications

Tier 2: Applied Integration Workshops

Process analysis augmentation

Pattern recognition enhancement

Predictive maintenance applications

Tier 3: Strategic Leadership Forums

Ethical considerations

Governance frameworks

Human-AI collaboration models

By the August meeting, this framework had materialized into a six-event webinar series with 10,000-participant capacity. The August 20 inaugural session featured Purdue Professor of Industrial Engineering Shahrukh Irani and Jamie Bonini, Lean Enterprise Institute's Senior Advisor and Community Manager, demonstrating that the improvement community could embrace rather than resist technological change. The second session in the series continued building on this foundation, featuring practical applications from early adopters across sectors.

Time Poverty: The Hidden Design Flaw

While AI anxiety grabbed attention, time poverty emerged as the universal constraint. Every sector used a different language for the same problem:

Team Leaders: "Always fire-fighting"

CI Professionals: "NO TIME FOR CI PROFESSIONAL OR FOR EMPLOYEES"

Healthcare: "Burden, engagement, psychological safety, patient satisfaction"—all competing for finite time

Service: "Devoting time to problem solving in 'live,' reactive environment"

But here's what the symposium revealed: this isn't a time management problem. It's a fundamental organizational design flaw. In pursuing efficiency, organizations have "optimized out all slack"—eliminated the very capacity needed for improvement and adaptation.

One team leader captured the paradox perfectly: "We're too busy to improve the things that make us too busy."

O.C. Tanner's Solution: Improvement as Standard Work

Gary Peterson's presentation offered a counter-narrative. O.C. Tanner didn't find more time—they redesigned work to include improvement. Their approach challenged the assumption that improvement is additional to "real work."

Key design principles:

Improvement ideas acknowledged within 48 hours: Not extra work but part of supervisor standard work

Visual management maintained by teams: Teams update their own boards as part of their daily work—not additional reporting layers for management

Coaching conversations daily: Not separate from operations but embedded in operations

Problem-solving during production: Not improvement events but improvement moments

This design philosophy—improvement as work, not added to work—offers a solution to time poverty that doesn't require finding more hours. The critical management discipline: when improvement creates capacity, leaders must decide how to allocate it. Without this deliberate choice, the freed-up time simply gets absorbed by other demands.

The Connection: AI as Time Creator

The breakthrough insight came when participants connected the dots: AI could create time for human-centered improvement work. Not by replacing people but by eliminating time-wasting activities.

Examples that emerged:

Automated report generation frees analysts for problem-solving

Pattern recognition identifies issues before they become crises

Predictive scheduling reduces fire-fighting

Documentation assistance for capturing tribal knowledge efficiently

Meeting summarization eliminating redundant communication

The Lean Into AI initiative evolved from addressing anxiety to enabling partnership. AI becomes the tool that creates capacity for the human work that adds value: creative problem-solving, relationship building, coaching, and innovation.

Once capacity is created through AI augmentation, leaders must actively allocate that time to value-adding activities. Without this deliberate management, organizations simply fill the void with more tasks rather than more improvement.

Framework for Implementation

The synthesis of discussions produced a practical framework for organizations. This emerged from symposium conversations and represents a starting point for further development:

Assessment Phase:

Map current time allocation (where does time actually go?)

Identify AI-augmentable tasks (what could technology handle?)

Evaluate data readiness (is our information AI-ready?)

Design Phase:

Embed improvement into standard work

Identify AI partnership opportunities

Create a learning infrastructure that supports continuous learning, with AI as one tool

Implementation Phase:

Start with low-risk augmentation

Build confidence through small wins

Scale based on demonstrated value

Actively reallocate freed-up time to creative problem-solving, relationship building, coaching, innovation, and other value-adding work

Moving from Fear to Partnership

The August update revealed organizations already experimenting with this partnership model. Shahrukh Irani described using ChatGPT and mind mapping tools to solve immediate problems at CPI Card Group—building credibility for deeper engagement. Educational institutions explored AI-enhanced learning analytics. Healthcare investigated clinical decision support systems.

The shift from "Will AI replace me?" to "How can AI help me?" represents more than acceptance—it's recognition that the relationship between human judgment and AI capabilities continues to evolve. While AI handles repetitive, analytical, pattern-based work effectively, the division of labor between humans and AI remains an active area of exploration in our community.

The Path Forward

Time poverty and AI anxiety aren't problems to solve but symptoms to address through organizational redesign. The solution isn't working harder or fearing technology, but redesigning systems where improvement is work and AI enables human contribution.

O.C. Tanner proved this is possible through 35 years of systematic implementation. The Lean Into AI initiative demonstrates it's achievable through structured learning. The question isn't whether to embrace this partnership but how quickly your organization can adapt.

Next: How plain language and creative engagement can make improvement accessible to the missing generation of practitioners.

Knowledge Map: Connecting to Your Context

Process Keywords: AI integration, time allocation analysis, standard work design, visual management, capacity creation, systematic implementation, augmentation strategy, predictive analytics, automation design, learning infrastructure, partnership models, organizational redesign

Context Keywords: Time poverty, AI anxiety, fire-fighting culture, workforce optimization, improvement capacity, technology adoption, data governance, competitive survival, existential questions, administrative burden, efficiency vs. adaptation, skill obsolescence

Application Triggers:

Facing "no time for improvement" complaints → Standard work redesign principles

Experiencing AI implementation anxiety → Three-tier learning framework

Dealing with constant fire-fighting → Time allocation mapping and AI-augmentable task identification

Managing technology adoption fears → Partnership model examples from symposium participants

Needing to justify improvement time → O.C. Tanner's improvement-as-work philosophy

Related Continual Improvement Themes: Organizational learning systems, standard work development, change management, technology integration strategy, capacity planning, lean leadership practices, problem-solving frameworks, workforce development, systems thinking

This blog series was co-created by the 110 participants of the FPW Symposium 2025, augmented with Claude.AI to capture and synthesize our collective insights. Special thanks to editors Dana Miller, Rachel Reuter, Bonnie Davis, and Joseph Pesz for their detailed review and improvements. Part six of nine documenting our journey toward workplace transformation. Join monthly discussions at www.fpwork.org.

It represents ongoing work by the Future of People at Work initiative, a collaboration of Catalysis, Central Coast Lean, GBMP Consulting Group, Imagining Excellence, Lean Enterprise Institute, Shingo Institute, The Ohio State University Center for Operational Excellence, and Toyota Production System Support Center.

Comments